Specs Oil Mist Detector

The world-wide recognition for the quality and function of its engine room oil mist detector (AOMD) and crankcase oil mist detector (COMD) has been achieved by Specs.

It also supplies various monitoring systems for ship safety and maintenance. The bearing wear monitoring system (BWMS) has also been developed by them so as to predict bearing wear in 2-stroke engines before the condition becomes critical. This system is responsible for providing an early warning alarm and a slow down signal if unexpected problems arise with any of the crank-train bearings, including crosshead, crank and main bearings.

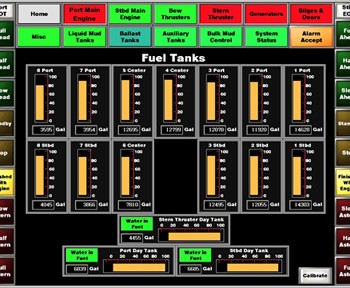

It also offers a ship energy efficiency monitoring system (SEEMS) which helps to collect real-time signals related to the efficiency and performance of ship operation, it also analyzes the information and stores the calculated data. Based on IMO guidelines, it calculates and displays EEOI & CO2 emission values, presents trend graphs of the data over variable time periods, and presents daily, voyage and sea trial reports.

The system enables engineers to maintain an optimum ship maintenance schedule, with more than 150 different data points.

SPECS OMD Detector Complete Stocks - Genuine Original Spares

Specs OMD Products

Internationally Certified Oil Mist Detectors

Oil Mist Detection System (OMD)

In order to reduce the fire risk from machinery space, flammable oil systems or explosions induced by oil mist inside diesel engine crankcases oil mist detector systems represent important measurements. The oil mist detector for the engine room (AOMD) and the model for the inside crankcase (COMD) by SPECS has obtained a reputation for top quality among global clients worldwide. They have acquired type approvals from major classification societies around the world to include its atmospheric oil mist detection system for engine rooms, crankcase oil mist detection system for diesel engines, and a new version of crankcase oil mist detection system for diesel engines.

Ship Performance Monitoring System

Bearing Wear Monitoring System (BWMS)

This is a very useful tool for predicting the bearing wear of 2 stroke engines before it becomes a critical condition. If an unexpected problem occurs at any of the crank-train bearings comprising crosshead, crank, and main bearings during engine operation the system provides early alarm or slow down signals.

Ship Energy Efficiency Monitoring System (SEEMS)

This monitoring system is considered to be the most useful and practical tool for monitoring, reporting, and verification of CO2 emissions and the energy efficiency of all ships. As it collects all real-time signals including the efficiency and performance of ship operations, analyzes, calculates them, and stores, displays, and reports all data.

Shaft Power Meter (SPM)

This shaft power meter system by SPECS is simple, but by adopting strain gauge and proximity sensor techniques it can measure and display shaft torque, thrust, power, RPM, rotating direction, revolutions accumulation, and transfer of power from the main engine to the propeller continuously. Easy installation of both kinds of new vessels and existing vessels in operation is possible. The measurement unit can be changed between metric and SI.

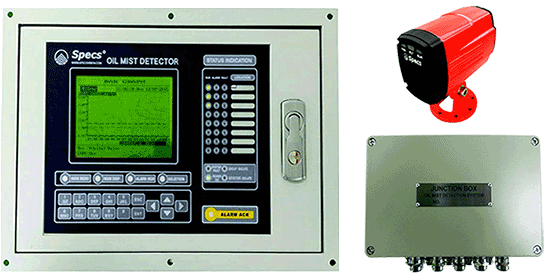

Specs Vision Atmospheric Oil Mist Detector AOMD

Detector Unit Vision IIA Multi Senor Remote Monitoring Unit (RMU) Junction Box

Atmospheric Oil Mist Detector (AOMD) developed in Specs Factory. It can accurately detect and activate alarms if there is oil mist in a marine engine crankcase or atmosphere in closed room condition.

Specs is the unique manufacturer for oil mist detectors In Korea, which is far superior to any other OMDs from the worldwide market.

Oil mist detectors by SPECS and its other products are suitable for the ShipBuilding Industry, LNG (Liquid Natural Gas) Tank, Telecommunication Industry, Electronic Industry, Industrial Measuring Instruments.

Authorized Dealer for Specs Vision Atmospheric Oil Mist Detector AOMD

AOMD-Atmospheric Oil Mist Detector-Specs VisionSYSTEM FEATURES-SPECS VISION ATMOSPHERIC OIL MIST DETECTOR AOMD

NEWEST VERSION BASED ON RECENT IACS

EFFECTIVENESS VERIFIED BASED ON M67 RULES

SUPERIOR ACCURACY VERIFIED

MOST RIGID CONSTRUCTION

INSTANTANEOUS RESPONSE TO ALARM

RS-485 / 422 TO IAS

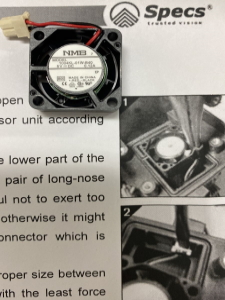

LESS CONTAMINATED SENSOR DESIGN

HIGHLY INTEGRATED SINGLE BOARD DESIGN

ROBUST ANTI-VIBRATION CONSTRUCTION

MULTI- FUNCTIONAL REMOTE MONITORING UNIT

PROVEN TEST AND CALIBRATION CHAMBER

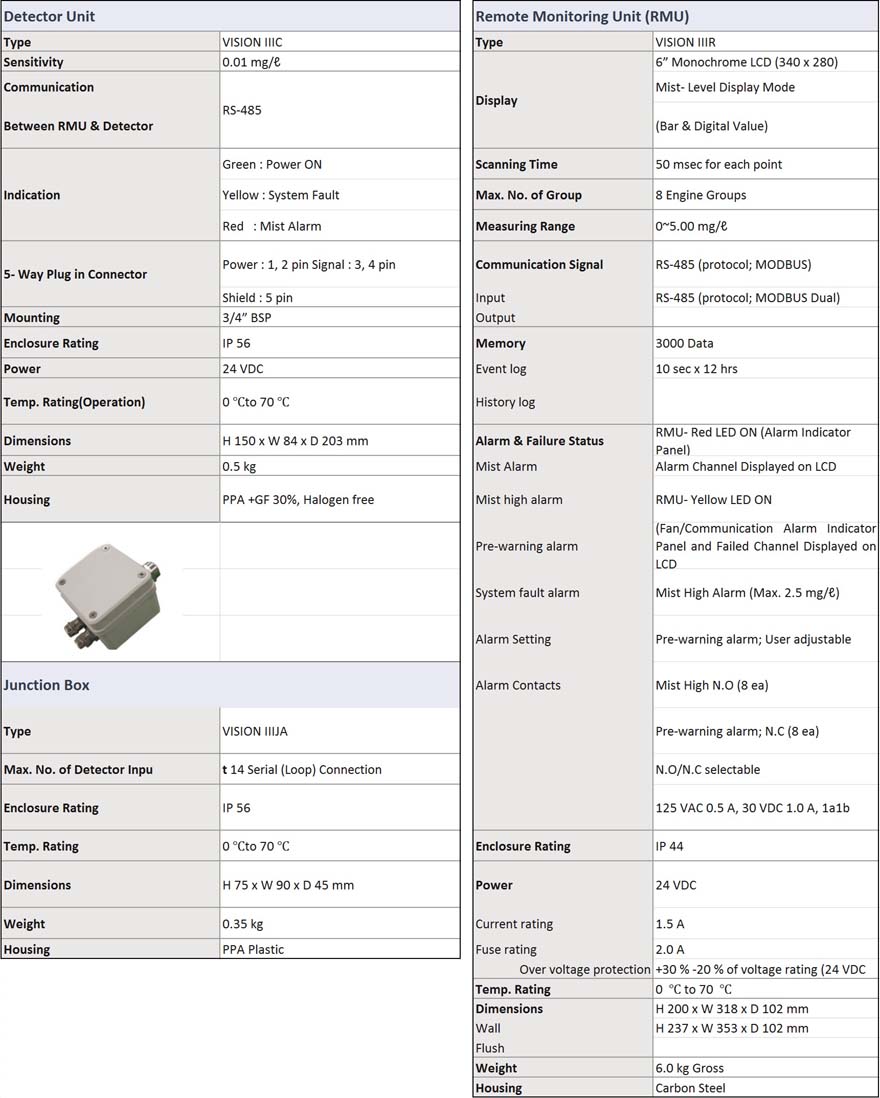

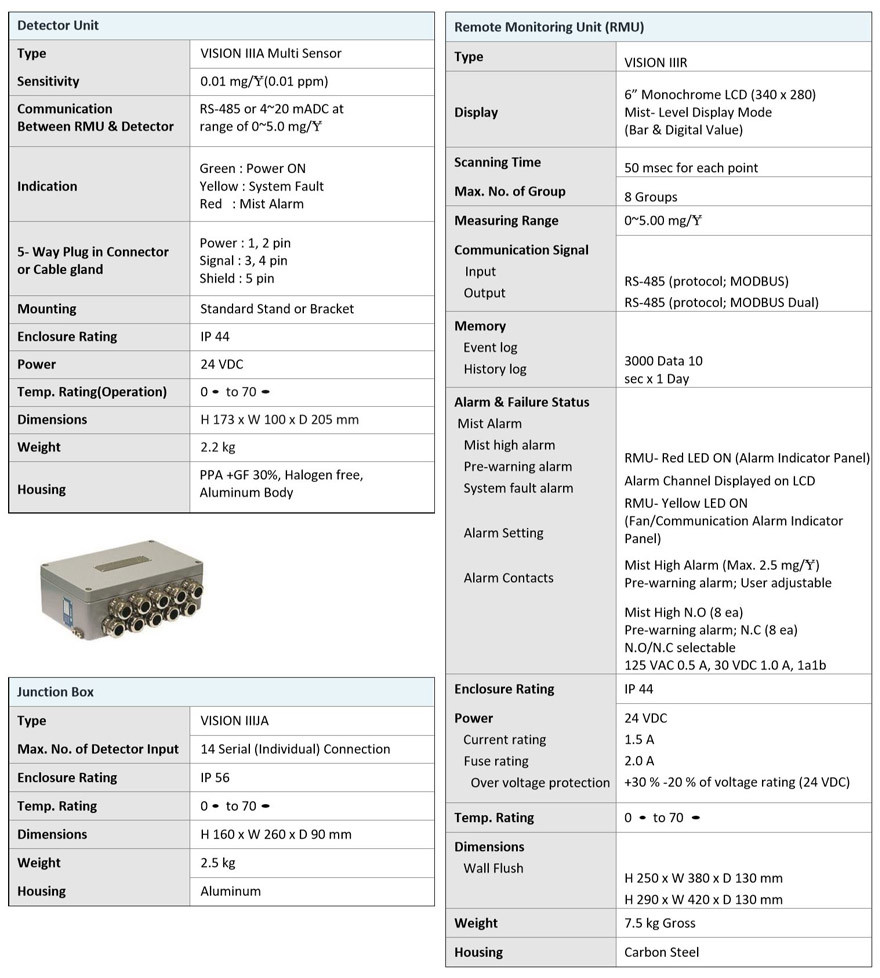

TECHNICAL SPECIFICATION-SPECS VISION ATMOSPHERIC OIL MIST DETECTOR AOMD

Specs Vision Crank Case Oil Mist Detector COMD

Remote Monitoring Unit Vision IIIR Junction Box Vision IIIJC

Crankcase Oil Mist Detector (COMD) developed in Specs Factory. It can accurately detect and activate alarms if there is oil mist in a marine engine crankcase or atmosphere in closed room condition.

Specs is the unique manufacturer for oil mist detectors In Korea, which is far superior to any other OMDs from the worldwide market.

Oil mist detectors by SPECS and its other products are suitable for the ShipBuilding Industry, LNG (Liquid Natural Gas) Tank, Telecommunication Industry, Electronic Industry, Industrial Measuring Instruments.

Authorized Dealer for Specs Vision Crankcase Oil Mist Detector COMD

Specs Vision Crank Case Oil Mist Detector COMDSYSTEM FEATURES-SPECS VISION CRANK CASE OIL MIST DETECTOR COMD

NEWEST VERSION BASED ON RECENT IACS

EFFECTIVENESS VERIFIED BASED ON M67 RULES

SUPERIOR ACCURACY VERIFIED

MOST RIGID CONSTRUCTION

INSTANTANEOUS RESPONSE TO ALARM

WORLDWIDE SUPPORT 24HRS

RS-485 / 422 TO IAS

LESS CONTAMINATED SENSOR DESIGN

HIGHLY INTEGRATED SINGLE BOARD DESIGN

ROBUST ANTI-VIBRATION CONSTRUCTION

MULTI- FUNCTIONAL REMOTE MONITORING UNIT

PROVEN TEST AND CALIBRATION CHAMBER

TECHNICAL SPECIFICATION-SPECS VISION CRANK CASE OIL MIST DETECTOR COMD